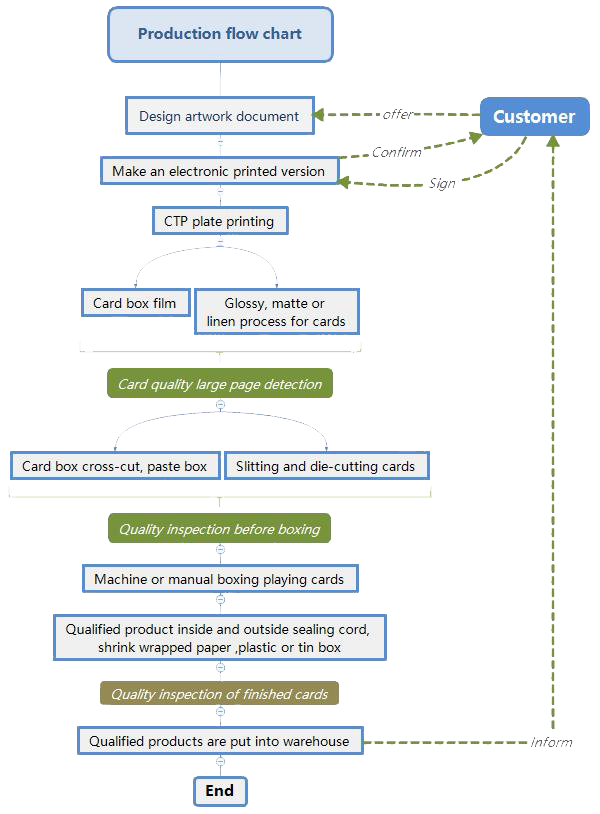

We use a picture to visualize it.

1. Get the client’s design manuscript. At the same time, an electronic printed version is produced for customers to check and confirm.

2. After the customer’s review and approval, the production contract is signed. Also pay the prepayment.

3. Cards, boxes and accessories are divided into three lines to arrange production tasks.

4. Print the arranged design version on special paper through a 4-color offset printing machine.

5. The first quality check.

6.1 Pass the printed card paper through the oiling machine to carry out the varnishing process.

6.2 Pass the printed box surface paper through the flim laminating machine or oiling machine for surface protection treatment.

6.3 Each accessory factory makes molds and completes injection molding and casting processes.

7. Glue the surface of the box and the inner lining of the box. Cards, boxes and accessories are dried separately for reinforcement.

8. Cutting, sorted and surface fixed.

9. Second quality check.

10. The cards are plastic-wrapped. (optional)

11. Put cards and accessories etc. into the box.

12. Complete the outer plastic-wrapped of the box.

13. After sampling inspection, put the finished product into the carton.

14. The products that pass the quality inspection are stored in the warehouse.

There are no shortcuts to the production process. Each step must be executed according to strict standards. The best performance of the machine can be used to produce satisfactory products.

If want to know more about factory production cards, please subscribe to RDCard.

Thanks for your reading